Production sites

Six sites in two countries

The main production site for Saarstahl AG is the Völklingen plant. Other core plants are the rolling mills in Völklingen (Nauweiler), Burbach and Neunkirchen. The main preliminary stages of production are consolidated at the Dillingen site. This includes coke production at Zentralkokerei Saar GmbH (ZKS) and hot metal production at ROGESA Roheisengesellschaft Saar. The Saarstahl Ascoval electric steel plant in France has been part of the Group since 2021; this route enables us to offer customers highly carbon-reduced steel. Another subsidiary, the Saarstahl Rail rolling mill in Hayange (France), produces high-quality rail infrastructure products.

Völklingen LD steelmaking plant

High-tech production and a broad quality spectrum

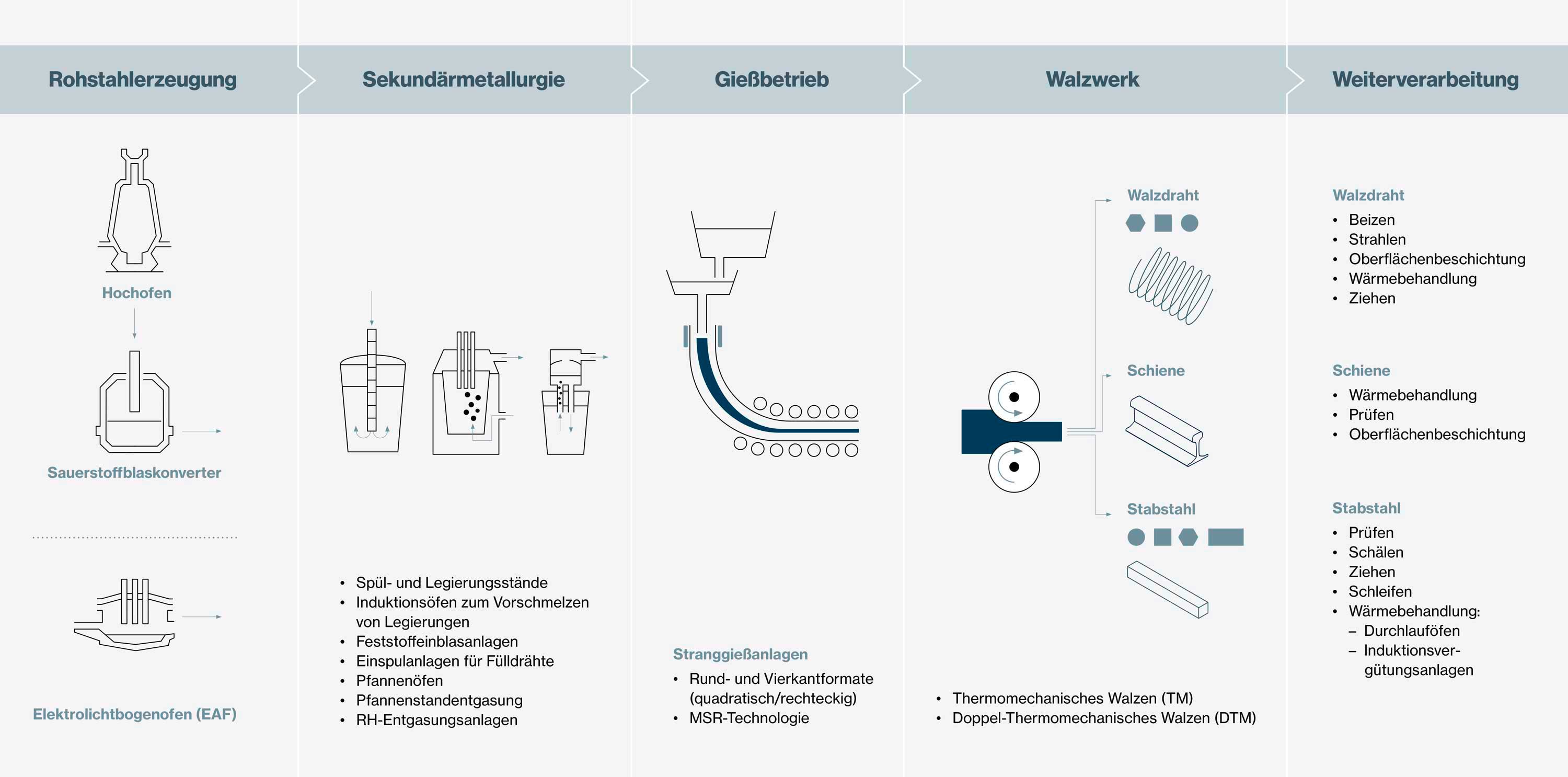

In the three 180-ton LD convertersand the four continuous casting machines at the distinctive LD steel plant, hot metal produced in the company’s own blast furnaces is cast into steel billets or blooms. Up to 2.7 million tons of steel are produced this way each year. The steel types include basic grades, alloyed and non-alloyed quality and special steels, cold heading grades, free cutting steels, gauze wire, soft drawing grades, welding wire, prestressing steels, and rope wire.

Computer-aided automation of production with state-of-the-art process control systems and program-controlled processes ensures a high degree of reproducibility – one of the core requirements of our customers. Continuous investments in system configuration, such as the recent addition of a new secondary metallurgy, state-of-the-art production techniques and an optimum flow of materials, ensure reliably high quality with respect to such aspects as the degree of purity, surface finish, lack of internal cracks, and segregation values. Saarstahl is a pioneer in Mechanical Soft Reduction (MSR), having developed the process in-house and subsequently bringing it to market maturity. Two systems are currently equipped with MSR technology. By investing in the S1 continuous casting machine, we were the first steel manufacturer in the world capable of producing the 180 mm x 180 mm casting format in conjunction with MSR technology.

Technical details:

- Three 180 t LD (BOF) converters

- Two twin ladle furnaces

- Two (RH) degassing systems

- Two bulk injection systems

- Five rinsing and alloy stands

- Three six-strand continuous casters

- Two five-strand continuous casters

Völklingen rolling mill

Our 1.2 kilometer long steel bar steel center

The bar steel center housed in the long production halls of the Nauweiler bar steel center is another technological highlight at the Völklingen site. Thanks to a consistent series of investments in the hundreds of millions, the rolling mill and the downstream bar steel processing plant have been systematically updated and expanded in recent years. The new continuous roughing mill (completed at the beginning of 2017) guarantees consistent high quality and efficiency in the rolling mill with greater flexibility regarding input and output cross-sections; the Kocks block (RSB) on mill 14 ensures excellent dimensional accuracy and tight tolerances. With the Nauweiler plant, we are positioned as a strategic international supplier of bar steel for highly demanding industrial sectors, particularly for the automotive industry.

Technical details:

- Joint roughing mill and intermediate mill with three duo-horizontal stands and seven-stand V/H continuous blooming line

- Annual capacity: 500,000 t – 700,000 t

- Continuous, computer-aided material flow tracking and process control

- Diameter testing with laser diameter

- Automated strapping

Burbach rolling mill

High-performance wire rod mill for thin wire rod dimensions

The Burbach rolling mill, one of our two wire rod production centers, is also located in Saarland. Its four-strand wire rod mill, with a dimensional range of 4.5 to 18 millimeters, is one of the world’s most efficient systems. The 4.5 mm dimension was produced in Burbach for the first time in Europe – with the option of eliminating heat treatments and with improved material properties on the drawn wire. With its wide range of products,Burbach is one of the world’s leading manufacturers of drawing grades. Each year the plant produces up to 1.2 million tons of wire that has repeatedly been recognized with awards from renowned tire manufacturers.

Technical details:

- Capacity: 1.2 million tons per year

- Fully continuous, 78 stands (including 4 x 10-stand finishing blocks)

- Stelmor cooling

- Computer-aided tracking of material flow and process management

- Diameter measurement with laser diameter

- Coil weights: min. 1,000 kg; max. 3,000 kg

- Barcode labelling

- Signode strapping of the coils

Neunkirchen plant

A 400-year history – with state-of-the-art production

The roots of the Neunkirchen plant stretch all the way back to 1593. This steel location has one of the richest histories in the world and it combines this history with state-of-the-art production in a unique way. With its two high-capacity rolling mills, highly automated semi-finished product preparation, and further processing adapted to special customer requirements, Neunkirchen now counts itself among the leading international manufacturers of long products. Highlights of the site include (D)TM rolling. Following the first installation of single thermo-mechanical (TM) rolling by loop on a wire rod mill worldwide, the extension of mill 32 for double thermomechanical (DTM) rolling in 2018 offers our customers improved wire rod properties. Additional investment in a blasting system (2023) enables descaling of wire rod using round blasting grit. Even pickling-resistant steel alloys can be descaled without leaving any residue. This process improves workability (already during the drawing process) and cold formability through a combination of blasting and coating.

Technical details:

Neunkirchen combined bar steel and wire rod mill

- Capacity: 600,000 tons per year

- Fully continuous, H/V arrangement, 21 stands

- 5-stand adjustable reducing sizing block for rolling limited tolerances for round and hexagonal bar

- Precision rolling line for square and flat material

- Thermomechanical rolling

- Coil weights: min. 1,000 kg; max. 3,000 kg

- Computer-aided tracking of material flow and process management

- Diameter measurement with laser diameter

- Barcode labelling

- Signode strapping of the coils

Neunkirchen wire rod mill (single strand wire rod mill)

- Annual capacity: 600,000 tons

- Fully continuous, 34 stands (incl. 4-stand precision finishing block)

- Loop cooling conveyor

- (Double) thermomechanical rolling

- Computer-aided tracking of material flow and process management

- Diameter measurement with laser diameter

- Barcode labelling

- Signode strapping of the coils

- (Wire rod: approx. 6.9–27.0 mm)